| Sign In | Join Free | My china-telecommunications.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My china-telecommunications.com |

|

Place of Origin : Shanghai, China

Brand Name : Leadworld

Voltage : 220V/380V, AC200V50/60Hz

Weight : 1500 KG

Material : Stainless Steel

Power supply : Three-phase 380V 50 Hz 16KW

Equipment length : 3000mm

Equipment width : 2500mm

Conveyor speed : 30m/min

Label feed speed : 100 meters/min

Labeling speed : 9000 BPH (500ml)

Labeling accuracy : ± 1mm

Maximum label width : 150mm

Maximum label length : 500mm

Maximum label diameter : 600mm

Paper core diameter : 152 mm

Gluing temperature : 120~160℃

Item | Data |

Transportation Structure | 750W motor,frequency converter speed regulation; Industrial nylon chain plate conveyor belt |

Mainframe transportation structure | motor 2.2Kw |

Bottle Separation structure | Feed screw |

Bottle Feeding structure | With the feed screw and star wheel position feeding structure to ensure the accuracy and stability of loading |

Position structure | Mechanical pre-location, using the cam wheel institution to planish the bottle for label positioning |

Labeling structure | Rotary type bottle tray carries the bottles, label during rotation |

Label feeding structure | high speed servo OPP label supply system (drive by servo-motor) |

Label pressing structure | Arc shape brush unit |

Bottle guiding structure | adjust by double coordinate section guide rail |

Glue supply system | hot melt glue supply system ensures the accuracy and uniformity of gluing |

Technical Parameter | ||

Item | Data | |

Power supply | Three-phase 380V 50 Hz 16KW | |

The total length of equipment | 3000mm (conveyor length 3000mm or can be regulate base on your product lines) | |

Equipment width | 2500mm | |

Conveyor speed | 30m/min (the speed of the transmission lines can be adjusted according to actual production) | |

The method of speed adjustment | uninterrupted - adjust rate | |

The largest Speed of labels feed | maximum speed of 100 meters labels / min | |

The largest speed of labeling | 9000 BPH (500ml) | |

Labeling accuracy | ± 1mm | |

Integrated Labeling accuracy | ± 1mm | |

Product Size | 500ml | |

Maximum label width | 150mm | |

The maximum length of label | 500mm | |

The maximum diameter of label | 600mm | |

Paper core diameter | 152 mm | |

Labeling glue | leading and trailing edge gluing with hot melt | |

Gluing temperature | 120~160℃ | |

Type of label | OPP label 、paper-plastic composite film label、paper label | |

Labeling workstation | 9 per cycle | |

Mold | Each set of molds include infeed screw, infeed star wheel, discharge star wheel, bottle tray and so on) | |

Machine weight | about 3000 Kg | |

|

|

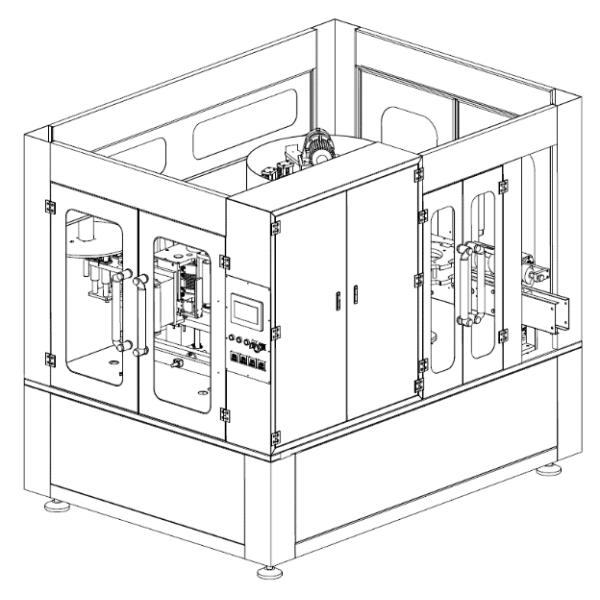

Servo-Driven High-Speed Labeling Machine for Round Bottles and Cans Images |